The HAPP™ - how it cleans

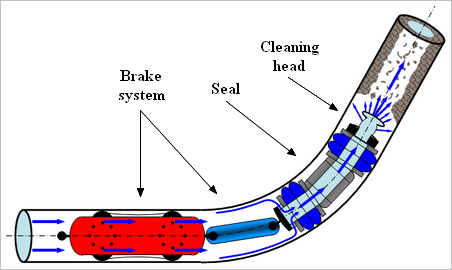

A Hydraulically Activated Power Pig (HAPP™) consists of three units: a brake unit, a seal unit and the cleaning head.

HAPP™ cleaning scheme

All units have openings that allow the entire fluid flow through the pipeline to bypass. The brake unit ensures that HAPP™ is held back against the fluid flow in the pipeline. The fluid pushes against the following seal unit, which channels it into the openings of the cleaning head. Seal unit and cleaning head pose a flow restriction resulting in a pressure difference across HAPP™. Thus the fluid is accelerated in the cleaning head's nozzles creating extremely powerful liquid jets. These jets are directed onto the pipe inner wall and remove any kind of deposits.

The brake unit ensures that the travel speed of a HAPP™ is up to 60 times slower than the fluid velocity thus allowing HAPP™ to entirely remove deposits from the pipe wall before it travels across the cleaned surface.

The deposits removed are immediately flushed downstream the pipeline with the main jet of the cleaning head which is directed in the middle of the pipeline. With all deposits removed from the pipe wall and transported downstream by the fluid flow there remains no risk of HAPP™ getting stuck in debris accumulated in front of it.